Test Alpha PX in a focused pilot. Measure real impact on downtime, maintenance efficiency, and technician performance.

If we don’t reduce your downtime or maintenance cost, you don’t pay

Manufacturers and field service organizations want results — not promises.

Our pilot program gives you a clear, low-risk path to evaluate how Alpha PX improves:

All without overhauling your existing systems or workflows.

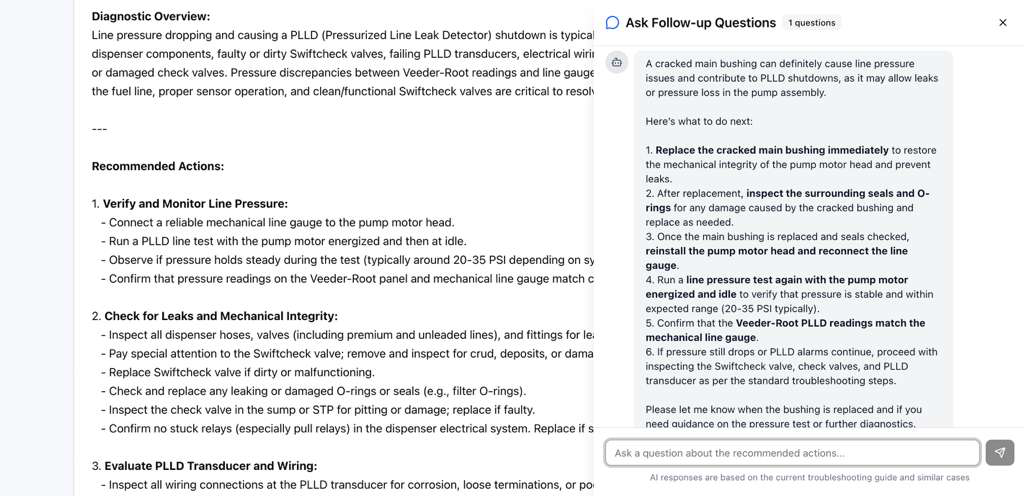

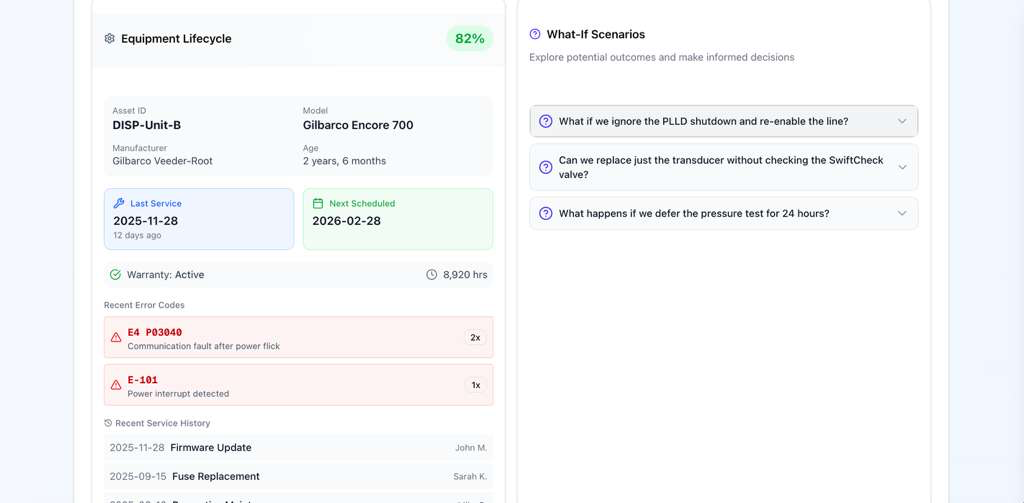

We begin by implementing the AI-powered technician knowledge base on one machine or line.

This includes:

This alone typically reduces troubleshooting time and repeat issues immediately.

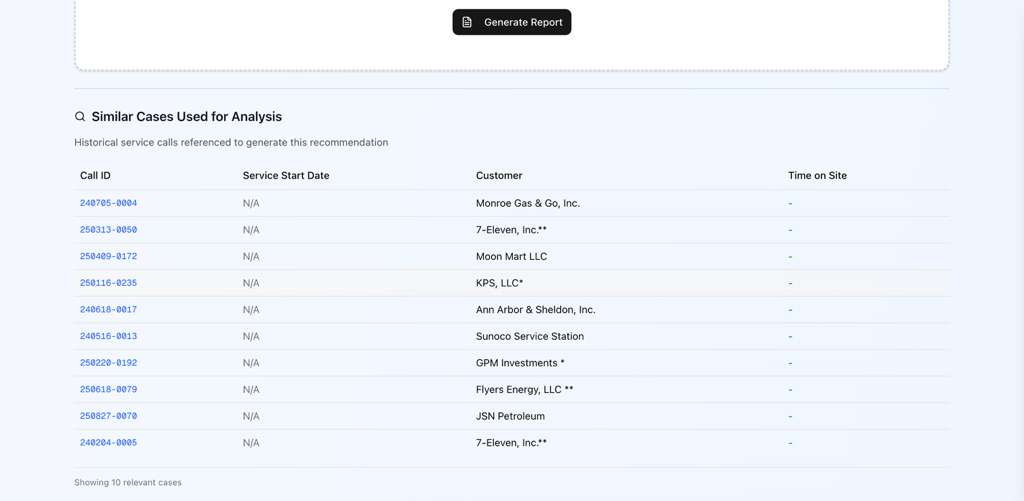

We analyze your historical maintenance data to build the foundation for predictive insights.

We analyze:

This builds the foundation for predictive insights.

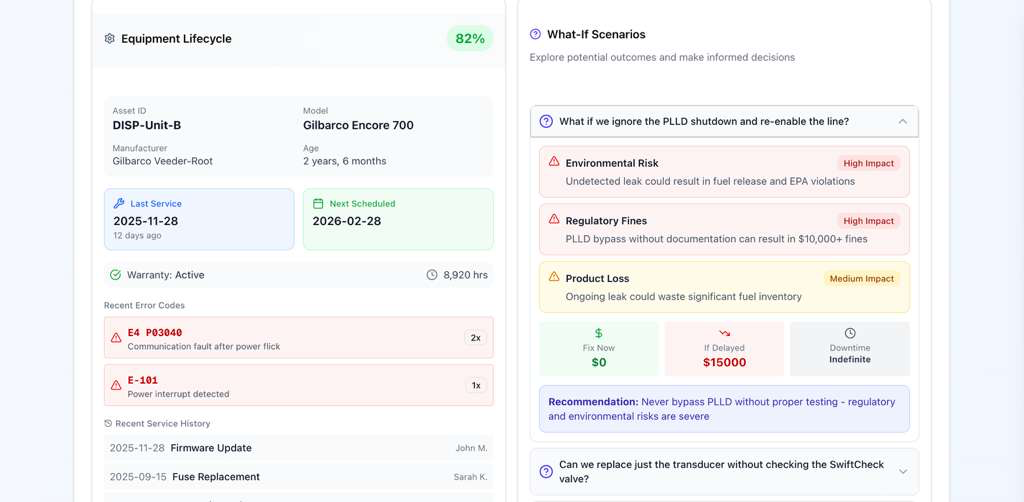

Where data allows, we provide insights that move you toward predictive maintenance.

We provide:

This is not yet full predictive maintenance — but it moves you toward it.

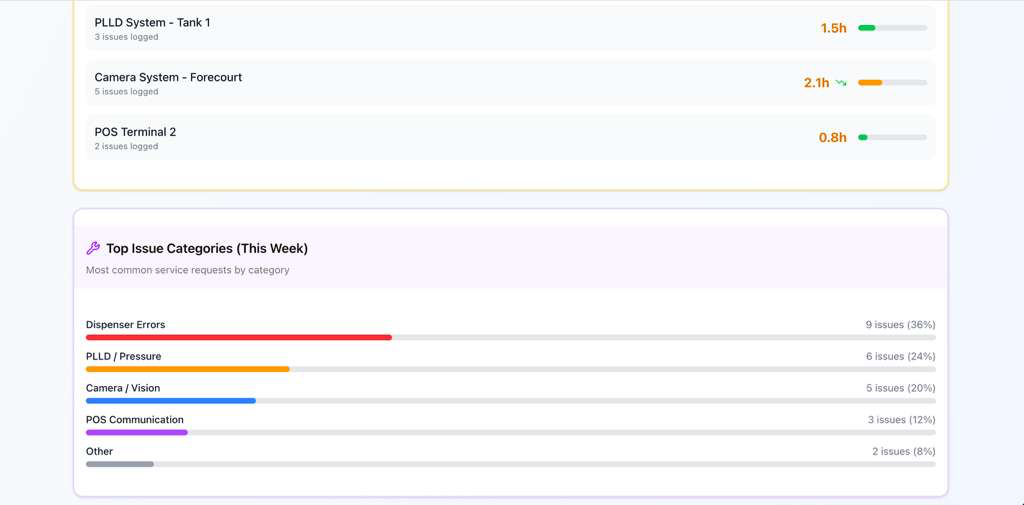

Plants often dedicate 8 hours each week to planned maintenance. With Alpha PX, you can reduce that window by targeting only what matters.

Pilot deliverables include:

At the end of the pilot, you receive a measured impact assessment.

The report includes:

You only pay if Alpha PX reduces downtime or maintenance-related cost.

Run the pilot on a small subset of equipment or locations.

Only pay if we reduce your downtime or maintenance cost.

No commitment required.

No commitment required.

No heavy IT lift.

No heavy IT lift.

Immediate value from the knowledge base.

Immediate value from the knowledge base.

Real results based on your data and operations.

Real results based on your data and operations.

Clear ROI based on downtime economics.

Clear ROI based on downtime economics.

Technician-friendly design.

Technician-friendly design.

It's everything a modern maintenance leader wants — without complexity.

Test Alpha PX on a single machine, a single line, or a single technician team and measure real impact.