From field operations to manufacturing environments, Alpha PX helps technicians fix issues faster, reduce downtime, and improve maintenance efficiency.

Below are examples of what Alpha PX delivers today — and emerging use cases we’re developing with industry leaders.

Case Study

A national field service provider was struggling with repeat visits, technician turnover, and inconsistent troubleshooting across regions.

Incorrect parts selection and escalating service tickets were driving cost and customer dissatisfaction.

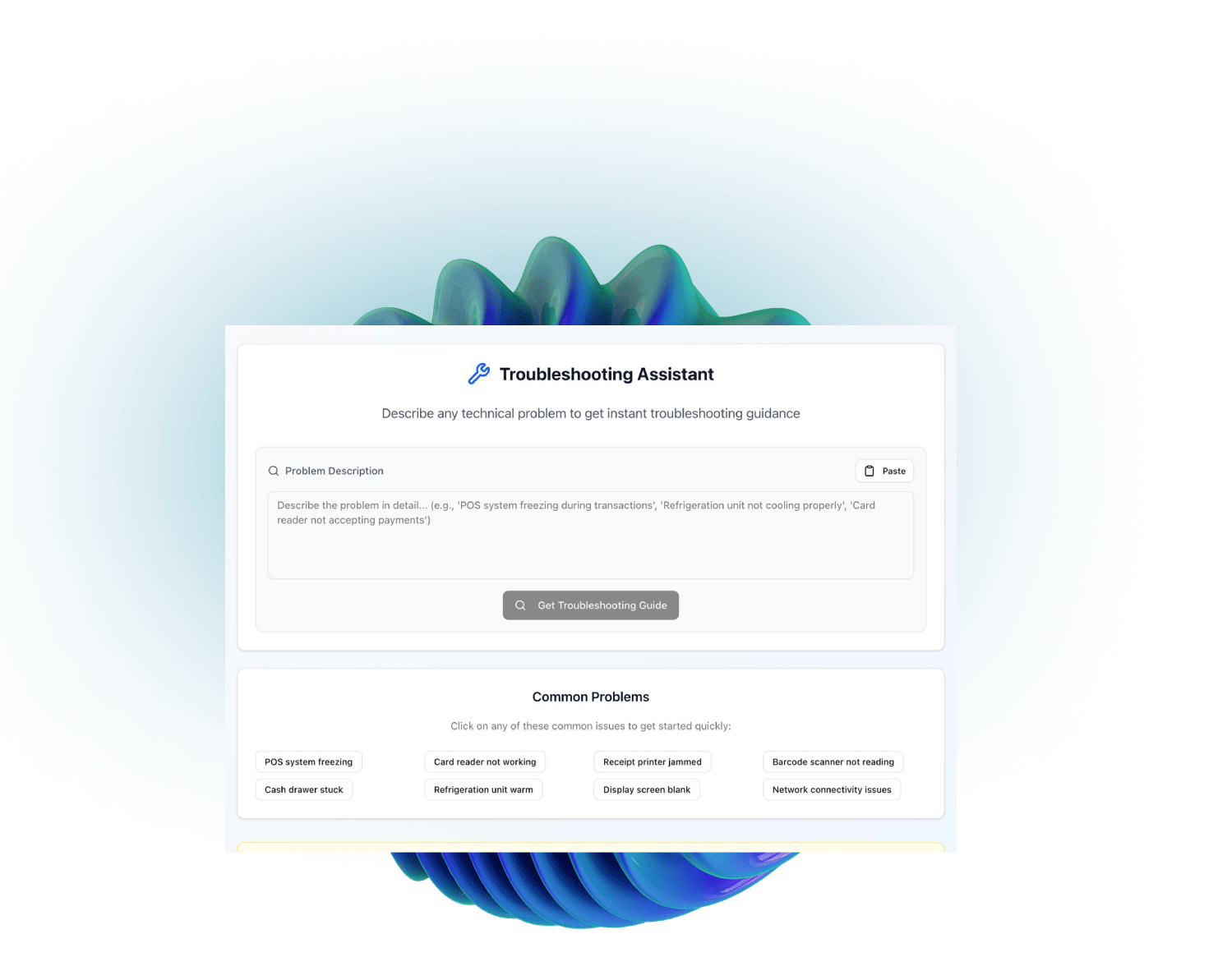

Alpha PX deployed an AI-powered technician knowledge base with guided troubleshooting and parts identification.

Technicians gained instant access to fix suggestions, step-by-step repair instructions, and historical resolutions captured from senior technicians.

Manufacturing Use Case (Emerging Work)

Manufacturers lose hours of productive time due to maintenance bottlenecks:

Alpha PX supports maintenance teams by:

While full manufacturing case studies are in development, early assessments and pilots focus on measurable improvements in maintenance efficiency and downtime reduction.

Sectors include automotive assembly, CNC machining, injection molding, robotics, tooling, aerospace, and industrial equipment.

AI-assisted troubleshooting and maintenance planning for public assets such as water systems, transit infrastructure, and building equipment.

Full insights will be published as part of our upcoming series on urban maintenance.

Support technicians with guided steps and parts intelligence to reduce charger downtime and improve site availability.

Support technicians with guided steps and parts intelligence to reduce charger downtime and improve site availability.

Help multi-site facility teams solve equipment issues faster and reduce vendor escalations.

Help multi-site facility teams solve equipment issues faster and reduce vendor escalations.

Pilot Program

Test Alpha PX on a single machine, a single line, or a single technician team.

We track the reduction in downtime, maintenance hours, and repeat visits.

If we don't reduce your cost or downtime, you don't pay.