Keep Operations Moving

Alpha PX helps maintenance teams keep equipment running with better knowledge, guidance, and early predictive insights.

A proven solution already used by national field service teams.

Alpha PX gives technicians instant access to the knowledge they need to diagnose and fix issues faster — reducing unplanned downtime and improving first-time fix success.

A low-risk, high-impact way to move toward predictive maintenance using your real operational data.

If we don't reduce downtime or maintenance cost by at least 30%, you don't pay.

Downtime is expensive. Alpha PX speeds up repairs and prevents avoidable failures.

Downtime is expensive. Alpha PX speeds up repairs and prevents avoidable failures.

Maintenance talent is hard to hire and keep. Alpha PX captures tribal knowledge and delivers it instantly at the point of repair.

Maintenance talent is hard to hire and keep. Alpha PX captures tribal knowledge and delivers it instantly at the point of repair.

Attrition erases expertise. Alpha PX speeds up training and ramps up new techs fast.

Attrition erases expertise. Alpha PX speeds up training and ramps up new techs fast.

Many plants dedicate a full shift each week to maintenance. Alpha PX reduces planned downtime through maintenance optimization.

Many plants dedicate a full shift each week to maintenance. Alpha PX reduces planned downtime through maintenance optimization.

Start with knowledge and guidance today, then evolve toward early warning signals that reduce risk and protect throughput.

Start with knowledge and guidance today, then evolve toward early warning signals that reduce risk and protect throughput.

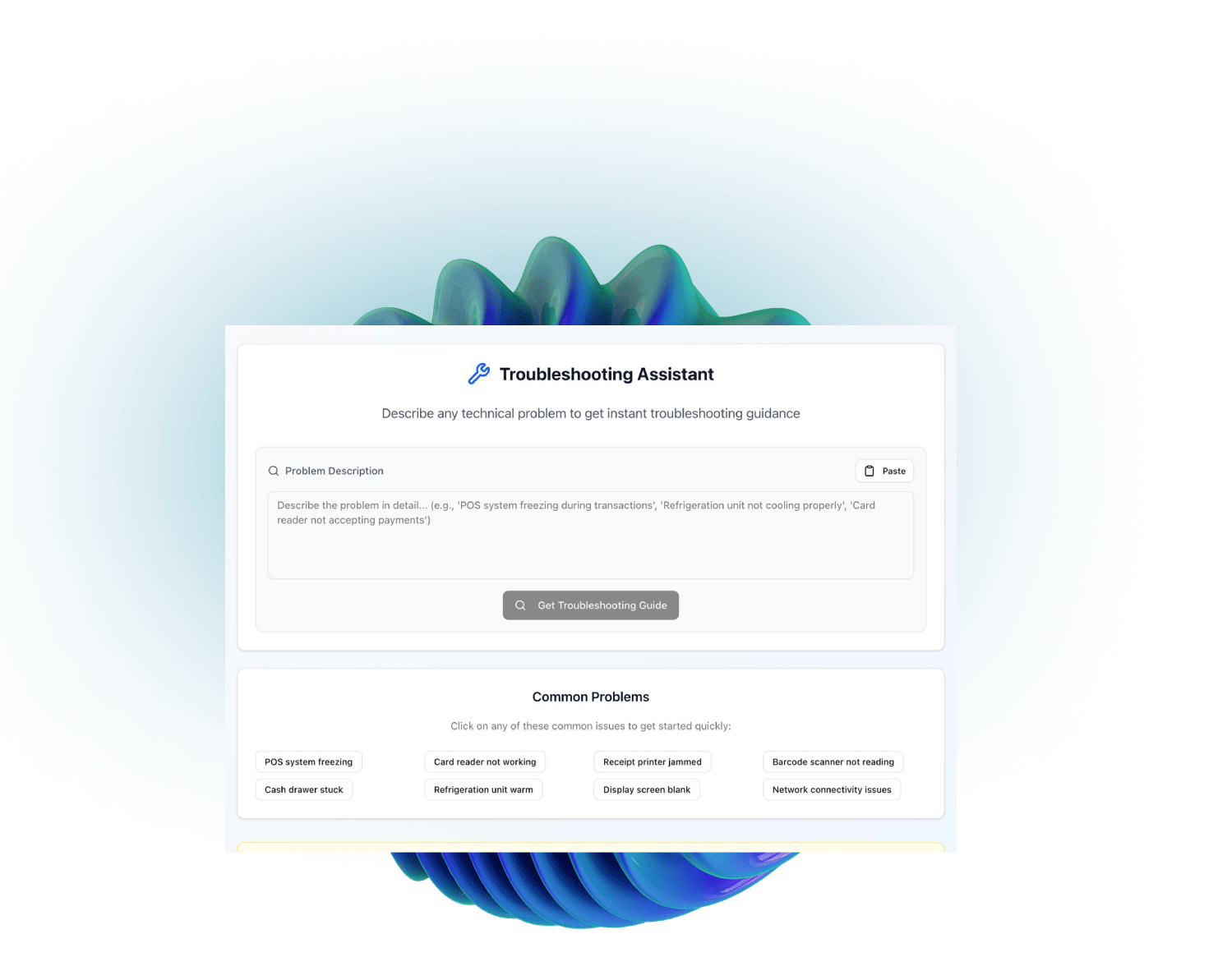

Support maintenance teams with guided troubleshooting, efficient maintenance planning, CNC and tooling insights, and reduced planned maintenance hours.

Improve first-time fix rates, reduce repeat visits, and support technicians with AI-powered knowledge for gas stations, EV chargers, elevators, and retail infrastructure.

Technicians receive step-by-step instructions and fix suggestions based on similar issues from your own machines and historical data.

Technicians receive step-by-step instructions and fix suggestions based on similar issues from your own machines and historical data.

Alpha PX highlights the most likely component causing the issue — with confidence scoring to guide replacements.

Alpha PX highlights the most likely component causing the issue — with confidence scoring to guide replacements.

Generate targeted, data-backed maintenance schedules and checklists that reduce over-maintenance and unnecessary downtime.

Generate targeted, data-backed maintenance schedules and checklists that reduce over-maintenance and unnecessary downtime.

Retain institutional expertise when senior technicians leave. Turn tribal knowledge into a structured system accessible to every shift.

Retain institutional expertise when senior technicians leave. Turn tribal knowledge into a structured system accessible to every shift.

Equip new technicians with instant, on-the-job guidance. Scale your workforce up or down without losing productivity.

Equip new technicians with instant, on-the-job guidance. Scale your workforce up or down without losing productivity.

Case Study

A national services provider used Alpha PX to reduce repeat visits, increase technician confidence, and ensure correct parts selection on the first trip.

Manufacturing Use Case

Manufacturers use Alpha PX to support technicians with guided troubleshooting, faster diagnosis, and more efficient maintenance planning — helping reduce unplanned downtime and reclaim productive hours.

A manufacturing pilot program is now available.

Pilot Program

Test Alpha PX on a single machine or assembly line with a free pilot license.

If we don't reduce your downtime or maintenance cost, you don't pay.